The term Recyclatanteil combines Recyclat (recycled material) and Anteil (share or proportion) to quantify the percentage of a product made from previously used materials. This metric is increasingly important in industries like packaging, plastics, and manufacturing, as it highlights sustainability efforts, reduces reliance on virgin resources, and supports a circular economy. Understanding it helps businesses, consumers, and policymakers make informed, eco-conscious decisions.

- What is Recyclatenteil?

- Why Recyclate Shapes Sustainable Production

- The Importance of Recycling

- How Recyclate is Calculated

- Key Considerations in Calculation

- Examples of Recyclate in Various Industries

- Challenges in Measuring and Increasing Recyclability

- Strategies to Improve Recyclate Rate

- The Role of Recyclate in Sustainable Certification

- Recyclatanteil and Circular Economy Goals

- Final Thought

What is Recyclatenteil?

Recyclatanteil combines the German words Recyclat (recycled material) and Anteil (share or proportion). It represents the percentage of a product made from materials that were previously used, recovered, and reintegrated into production. This metric is essential in sustainable manufacturing, helping companies measure environmental impact, comply with regulations, reduce reliance on virgin resources, and promote circular economy practices, while informing consumers about the product’s recycled content.

Why Recyclate Shapes Sustainable Production

Recyclate percentage is a key indicator of a product’s environmental responsibility. By measuring the share of recycled materials, it reduces reliance on virgin resources, lowers waste, and decreases carbon emissions. For businesses, it strengthens sustainability credentials and regulatory compliance; for consumers, it enables informed, eco-friendly choices. Embracing Recyclatanteil fosters a circular economy, turning previously used materials into valuable resources while promoting long-term ecological and economic benefits.

The Importance of Recycling

1. Environmental Benefits

- Waste reduction: it promotes the circular economy by reintegrating materials that would otherwise end up in landfills or incinerators.

- Lower carbon footprint: Recycling generally consumes less energy than producing new materials, reducing greenhouse gas emissions associated with manufacturing.

2. Economic Advantages

- Cost efficiency: In some cases, recycled materials are cheaper than virgin alternatives, lowering production costs.

- Market differentiation: Products with a higher it can be marketed as eco-friendly, appealing to increasingly environmentally conscious consumers.

3. Social and Regulatory Relevance

- Consumer awareness: As sustainability becomes a purchasing criterion, it allows consumers to make informed choices.

- Compliance with legislation: Many regions, including the European Union, have set regulations mandating minimum recycled content in certain products, particularly packaging. it is a quantifiable way to demonstrate compliance.

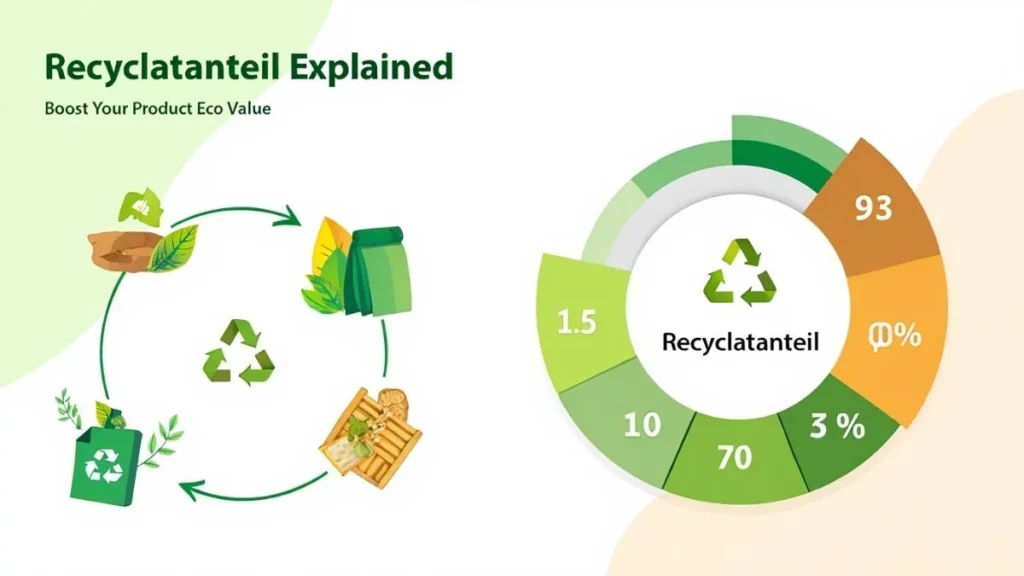

How Recyclate is Calculated

The calculation of Recyclatanteil varies depending on the type of material and industry. Generally, it follows this formula:

Recyclatanteil (%) = (Weight of recycled material ÷ Total material weight) × 100

Key Considerations in Calculation

- Type of Recycled Material: Post-consumer versus post-industrial recycled materials may be accounted for differently. Post-consumer materials come from products that have reached the end of their lifecycle, while post-industrial materials are leftovers from manufacturing processes.

- Material Purity: Contaminants or mixed materials can affect the effective it. Higher purity often means higher environmental and functional value.

- Functional Equivalence: In some cases, substituting virgin material with recycled material may affect product performance. Companies must ensure that recycled content meets quality standards.

Examples of Recyclate in Various Industries

1. Plastic Packaging

Recyclatanteil is commonly used in the plastics industry, where the demand for recycled content in packaging is growing. Bottles, containers, and films often indicate their it to show compliance with regulatory standards and sustainability goals.

2. Automotive Industry

Modern vehicles are increasingly designed with recycled materials, from plastics to metals. A car might contain 25 to 30% recycled plastic parts, contributing to both weight reduction and environmental sustainability.

3. Electronics

Electronic devices, such as smartphones and laptops, often incorporate metals recovered from old devices. Monitoring Recyclatanteil in electronics helps companies meet directives like the EU’s Waste Electrical and Electronic Equipment (WEEE) regulations.

4. Construction Materials

Concrete, steel, and insulation materials can include recycled content. For instance, recycled steel can maintain structural strength while lowering CO₂ emissions compared to virgin steel.

Challenges in Measuring and Increasing Recyclability

- Material Quality Variability: Recycled materials often differ in purity and composition, affecting product performance.

- Supply Chain Limitations: Inconsistent availability of high-quality recycled materials can hinder production planning.

- Complex Product Designs: Products made from mixed or composite materials are harder to recycle effectively.

- Regulatory Compliance: Varying standards across regions make tracking and reporting the Recyclatanteil challenging.

Strategies to Improve Recyclate Rate

To increase Recyclatanteil, companies can invest in advanced material recovery and sorting technologies, design products for easy disassembly and recyclability, and establish reliable partnerships with recycled material suppliers. Implementing take-back programs and promoting consumer recycling also enhances the availability of post-consumer materials. These strategies not only boost recycled content in products but also strengthen sustainability credentials, reduce environmental impact, and support circular economy objectives.

The Role of Recyclate in Sustainable Certification

Sustainability certifications often include Recyclatanteil as a key metric:

- Cradle to Cradle (C2C) Certification: Evaluates products based on material health, reutilization, renewable energy use, water stewardship, and social fairness. Recyclatanteil directly influences material reutilization scoring.

- ISO 14021 Environmental Labels: Guides self-declared recycled content, requiring measurable Recyclatanteil and verifiable data.

- LEED Certification for Buildings: Construction projects with high Recyclability in materials like steel, concrete, and insulation earn credits toward green building standards.

Recyclatanteil and Circular Economy Goals

Recyclatanteil plays a crucial role in advancing circular economy objectives by keeping materials in use longer and reducing waste. By maximizing recycled content in products, companies conserve natural resources, lower greenhouse gas emissions, and minimize landfill reliance. Monitoring and improving the Recyclatanteil supports sustainable production, encourages innovative material recovery, and helps businesses align with global circular economy standards and eco-conscious consumer expectations.

Final Thought

Recyclatanteil is more than a metric; it reflects a product’s commitment to sustainability and responsible resource use. By measuring and increasing the share of recycled materials, companies reduce environmental impact, comply with regulations, and enhance brand credibility. Integrating it into production supports circular economy goals, promotes innovation in material reuse, and empowers consumers to make environmentally conscious choices, paving the way for a more sustainable and resource-efficient future.