Laser cutters are widely used in manufacturing, crafting, and industrial production due to their ability to cut, engrave, and mark materials with high precision and consistency.

However, the term laser cutter does not refer to a single technology.

Different laser sources are designed for different materials, applications, and budgets.

Selecting the wrong type can lead to poor results, higher costs, or limited scalability.

This guide focuses on the three most relevant and widely adopted laser cutter technologies today—CO₂, Fiber, and Diode—and explains how to choose the right one based on real-world use cases.

1. CO₂ Laser Cutters: Best for Non-Metal Materials

CO₂ laser cutters are among the most commonly used laser machines and are well known for their versatility with organic and non-metal materials.

How It Works

- Uses a sealed gas tube filled primarily with carbon dioxide

- Electrical excitation produces an infrared laser beam (~10.6 μm)

- The beam is reflected by mirrors and focused onto the material

Best-Suited Materials

- Wood and plywood

- Acrylic (especially clear acrylic)

- Leather

- Paper and cardboard

- Fabric and textiles

- Rubber, cork, and selected plastics

- Glass and certain ceramics (engraving only)

Common Applications

- Signage and display production

- Crafts and personalized gifts

- Architectural models and prototypes

- Fashion and textile cutting

- Awards and trophies

Advantages

- Wide compatibility with non-metal materials

- Excellent engraving quality

- Mature and well-supported technology

- Lower entry cost compared to industrial metal lasers

Limitations

- Cannot cut or engrave bare metals

- Requires regular maintenance (mirrors, lenses, tube replacement)

- Larger machine footprint

Typical Power Range

- 30W–300W+

2. Fiber Laser Cutters: High-Speed Metal Processing

Fiber lasers are the industry standard for metal cutting and marking, especially in industrial and professional manufacturing environments.

How It Works

- Solid-state laser generated through doped optical fiber

- Pumped by laser diodes instead of gas

- Shorter wavelength (~1.06 μm) with high absorption in metals

Best-Suited Materials

- Stainless steel

- Carbon steel

- Aluminum

- Brass and copper

- Titanium and metal alloys

Common Applications

- Industrial metal fabrication

- Automotive and aerospace components

- Medical device manufacturing

- Jewelry engraving

- Serial number and barcode marking

Advantages

- Extremely fast cutting speeds on metals

- High precision and repeatability

- Very low maintenance

- High energy efficiency

- Long laser source lifespan

Limitations

- High upfront cost

- Not suitable for wood, acrylic, leather, or fabric

- Requires strict laser safety standards

Typical Power Range

- 20W (marking) to 20,000W+ (industrial cutting)

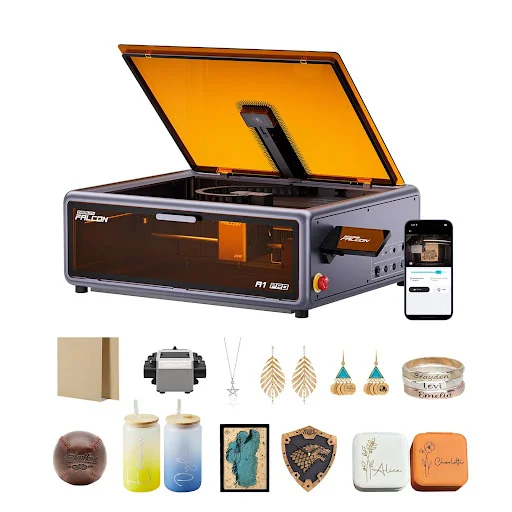

3. Diode Laser Engravers: Entry-Level and Desktop Use

Diode laser engravers are widely used by hobbyists, educators, and small workshops due to their affordability and compact size.

How It Works

- Uses semiconductor laser diodes

- Operates in the blue light spectrum (~450 nm)

- Direct emission without mirrors or gas tubes

Best-Suited Materials

- Wood

- Paper and cardboard

- Leather

- Dark or coated acrylic

- Coated or anodized metals (surface marking only)

Common Applications

- DIY and maker projects

- Educational settings

- Light crafting and personalization

- Small desktop workshops

Advantages

- Lowest entry cost among laser types

- Compact, lightweight, and portable

- Easy to learn and operate

- Low power consumption

Limitations

- Limited cutting depth and speed

- Cannot cut clear acrylic or bare metals

- Often requires multiple passes

- Not suitable for high-volume production

Typical Power Range

- 5W–40W (optical output)

Key Factors When Choosing a Laser Cutter

1. Material Compatibility

- Non-metals (wood, acrylic, leather) → CO₂ or Diode

- Metals → Fiber

2. Primary Application

- Deep cutting vs. surface engraving

- Speed requirements

- Level of detail and consistency

3. Budget Considerations

- Initial machine cost

- Maintenance and consumables

- Long-term operating cost

4. Production Scale

- Hobby or small-batch work

- Commercial production

- Industrial manufacturing

5. Workspace and Safety

- Ventilation and exhaust requirements

- Electrical capacity

- Laser safety compliance

6. Future Expansion

- New materials

- Higher throughput

- Business scalability

Comparison Table: CO₂ vs. Fiber vs. Diode Lasers

| Feature | CO₂ Laser | Fiber Laser | Diode Laser |

| Primary Materials | Non-metals | Metals | Soft non-metals |

| Main Use | Cutting & engraving | Metal cutting & marking | Engraving, light cutting |

| Power Range | 30W–300W+ | 20W–20kW+ | 5W–40W |

| Initial Cost | Medium | High | Low |

| Maintenance | Moderate | Low | Very low |

| Cutting Speed | Medium | Very high | Low |

| Precision | High | Very high | Medium |

| Best For | Acrylic, wood, leather | Steel, aluminum, copper | DIY & desktop use |

Conclusion

Laser cutters are not interchangeable tools. Each technology is designed for a specific set of materials and applications.

- CO₂ lasers are ideal for non-metal materials and creative work

- Fiber lasers dominate metal cutting and industrial production

- Diode lasers provide an accessible entry point for beginners

By clearly defining your materials, applications, and production goals, you can confidently choose the laser cutter technology that fits your needs today and scales with you tomorrow.