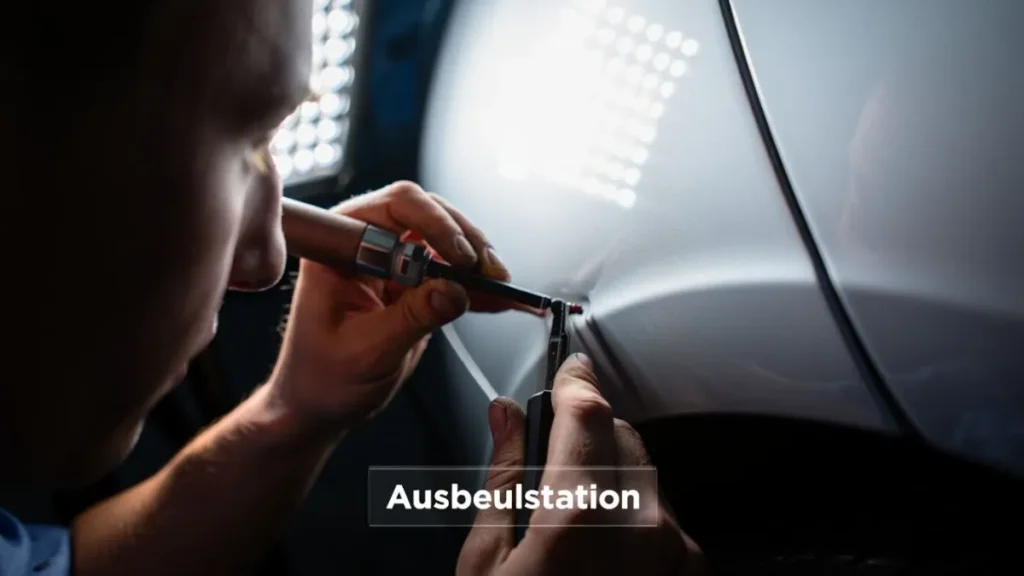

An Ausbeulstation is a specialized workstation in automotive body repair facilities dedicated to dent removal, panel reshaping, and structural correction. Derived from the German word ausbeulen (“to remove dents”), it is designed as a controlled environment for precise metal restoration rather than a general repair area. Equipped with calibrated tools and ergonomic workstations, the Ausbeulstation enables technicians to efficiently correct cosmetic and structural damage in accordance with manufacturer-compliant procedures. This precision-focused zone ensures vehicles are restored to both aesthetic and structural standards.

- The Role of the Ausbeulstation in Collision Repair

- Core Functions and Capabilities

- Equipment and Tooling in an Ausbeulstation

- Safety and Compliance in the Ausbeulstation

- Techniques Employed in an Ausbeulstation

- Ausbeulstation vs. Conventional Workspaces: Advantages of a Dedicated Station

- Challenges and Considerations

- The Ausbeulstation in Sustainable Repair

- Training and Certification for Ausbeulstation Technicians

- FAQs

- Final Thoughts

The Role of the Ausbeulstation in Collision Repair

The Ausbeulstation serves as a precision-focused area within collision repair facilities, dedicated to correcting dents, reshaping panels, and restoring structural integrity. Providing a controlled workspace with specialized tools and ergonomic supports allows technicians to apply calibrated forces accurately. This ensures vehicles are repaired efficiently, preserving both aesthetic quality and safety standards, while minimizing filler use and adhering to manufacturer-recommended procedures.

Core Functions and Capabilities

- Dent Removal: Using calibrated hammers, dollies, suction devices, and pullers, technicians carefully restore the original contour of metal panels without compromising structural integrity.

- Panel Reshaping: Advanced techniques such as shrinking, stretching, or gently massaging the metal allow for precise contouring of vehicle surfaces. This ensures alignment with factory specifications and preserves the aesthetics of the car.

- Structural Correction: In cases of more severe collision damage, the Ausbeulstation supports frame and subframe adjustments, ensuring that repaired vehicles meet safety standards and manufacturer guidelines.

Equipment and Tooling in an Ausbeulstation

Modern Ausbeulstations are outfitted with a variety of specialized tools designed for precision and efficiency:

- Dent Pullers: Hydraulic and mechanical pullers that restore panel shape without removing paint.

- Hammers and Dollies: Ergonomically designed tools allow technicians to apply force in controlled increments.

- Heat Shrinking Devices: Used to shrink stretched metal panels without warping adjacent areas.

- Measuring Systems: Laser or digital measuring devices ensure repairs align with factory dimensions.

Each tool is selected based on the material type (steel, aluminum, or composite panels) and the degree of damage, enabling a tailored approach to every repair.

Safety and Compliance in the Ausbeulstation

Ensuring safety and regulatory compliance is crucial in an Ausbeulstation. Technicians use clamps, alignment gauges, and protective equipment to prevent accidents and improper repairs. All procedures follow manufacturer specifications to maintain structural integrity, especially in critical areas like crumple zones and airbag systems. Controlled environments, proper ventilation, and ergonomic setups minimize risk, guaranteeing that each repair meets industry standards while protecting both the vehicle and the technician.

Techniques Employed in an Ausbeulstation

- Pushing and Pulling: Skilled technicians apply force in precise directions to gradually return the metal to its original contour. This often involves a combination of pulling with specialized devices and pushing with dollies or hammers.

- Heat Application: Some metals, particularly aluminum, require localized heating to make the metal more malleable. It provides controlled heating tools to avoid warping or weakening surrounding areas.

- Dent Spotting and Measurement: Advanced incorporates laser measurement devices or digital profiling tools that allow technicians to compare repaired panels against factory specifications, ensuring structural and aesthetic accuracy.

Ausbeulstation vs. Conventional Workspaces: Advantages of a Dedicated Station

| Feature/Aspect | Dedicated Ausbeulstation | Conventional Repair Workspace |

| Precision | Calibrated tools and controlled environment enable exact dent and panel correction. | Limited tool organization can result in inconsistent repairs. |

| Efficiency | Ergonomic layout and material-specific setups streamline workflow. | Technicians spend more time locating tools and adapting methods. |

| Safety & Compliance | Adheres to manufacturer guidelines with proper fixtures, gauges, and protective measures. | Higher risk of improper repairs due to ad hoc setups. |

| Material Handling | Specialized in high-strength steel, aluminum, and composites. | May lack the capability for modern automotive materials. |

Challenges and Considerations

- Training Requirements: Technicians must undergo specialized training to understand material properties, repair techniques, and manufacturer protocols.

- Equipment Costs: High-quality, calibrated tools and measurement systems represent a significant initial investment.

- Space and Layout: Establishing a dedicated station requires sufficient space and careful planning to avoid workflow bottlenecks.

- Technological Updates: Continuous advancements in automotive materials and repair techniques demand ongoing equipment upgrades and staff education.

The Ausbeulstation in Sustainable Repair

The Ausbeulstation promotes sustainable automotive repair by minimizing part replacements and reducing material waste. Precision dent removal and panel reshaping conserve resources and lower energy consumption in manufacturing new components. Correct repairs extend vehicle lifespan, decrease environmental impact, and limit chemical usage in painting. By combining efficiency with material-conscious techniques, it supports eco-friendly practices while maintaining high-quality, manufacturer-compliant repairs.

Training and Certification for Ausbeulstation Technicians

Operating an Ausbeulstation requires specialized training and certification. Technicians learn metal forming techniques, manufacturer-specific repair procedures, and safety protocols to ensure precise, compliant repairs. Certification programs validate expertise, covering dent removal, panel reshaping, and structural correction. Skilled, certified technicians enhance repair quality, maintain safety standards, and build customer trust, ensuring that every vehicle is restored efficiently while meeting industry and manufacturer requirements.

FAQs

1. Is it suitable for modern vehicles with aluminum or composite panels?

Yes, modern machines are equipped to handle high-strength steel, aluminum, and composite materials using tailored tools and techniques.

2. What safety measures are implemented?

Technicians use clamps, alignment gauges, protective gear, and controlled environments to prevent accidents and ensure manufacturer-compliant structural repairs.

3. Can it improve efficiency in a body shop?

Absolutely. With organized layouts, specialized tools, and workflow optimization, it reduces repair time while maintaining precision.

Final Thoughts

The Ausbeulstation exemplifies precision, efficiency, and professionalism in modern automotive repair. By combining specialized tools, ergonomic design, and manufacturer-compliant techniques, it ensures high-quality results while supporting sustainability and safety. Investing in a dedicated station enhances workflow, reduces material waste, and fosters technician expertise. Ultimately, it reflects a commitment to excellence, protecting both vehicles and the environment while meeting the evolving demands of today’s collision repair industry.